Partnering with BMP Medical

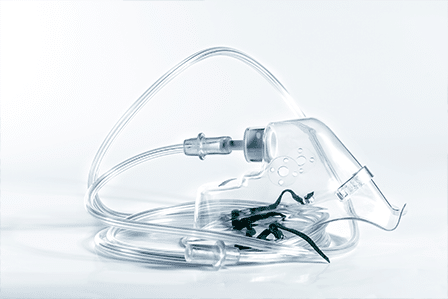

We do more than manufacture, we invest in your success. As a trusted medical injection molding supplier, we work side by side with OEMs to secure long-term and shared growth.

Learn More About Our ServicesDesign and Development

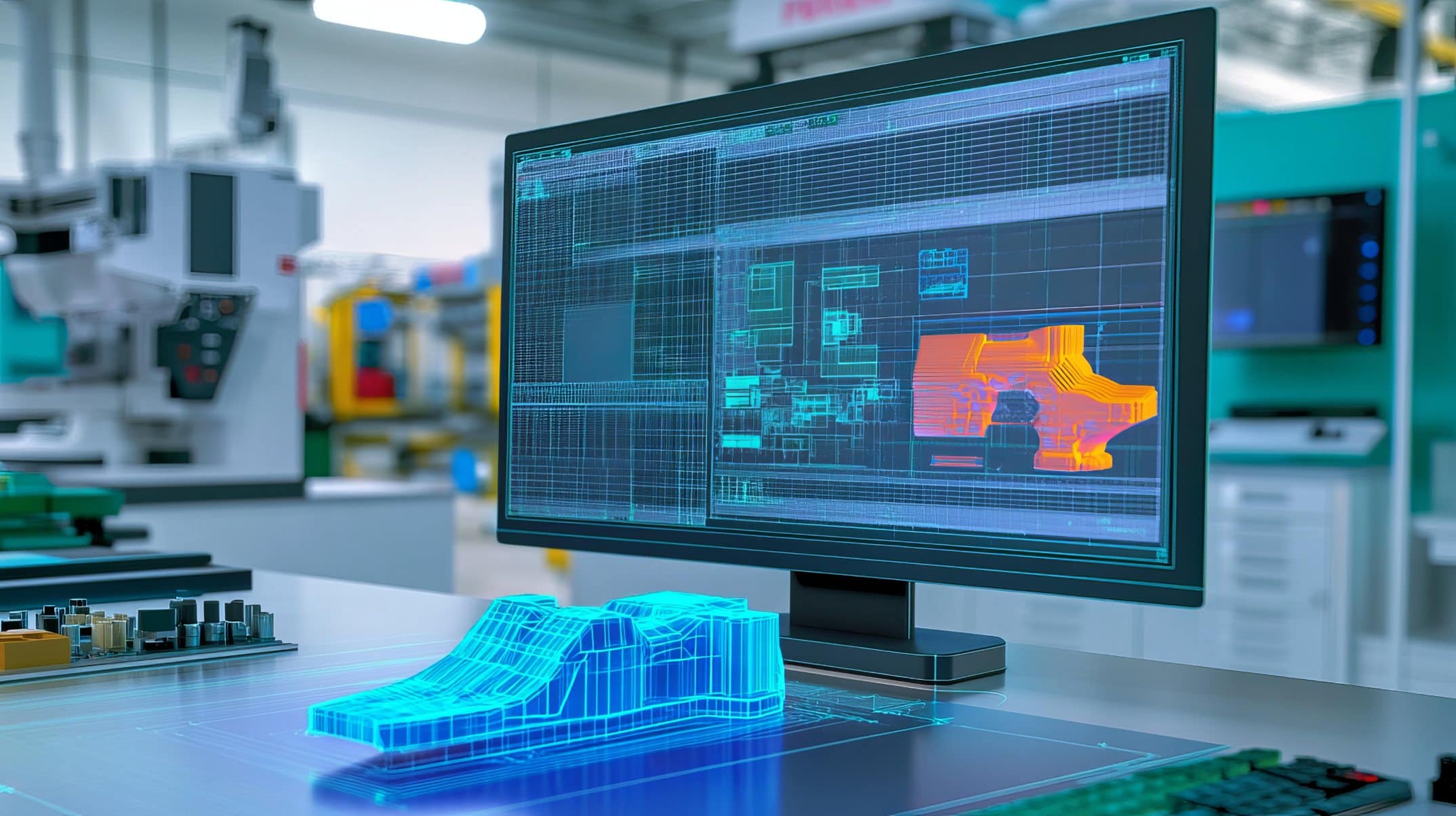

Great products start with great design. We collaborate with OEMs to refine ideas, select the right materials, and optimize designs for manufacturability—helping bring reliable medical components to market faster.

View Design & Development ServicesExpert Consultation

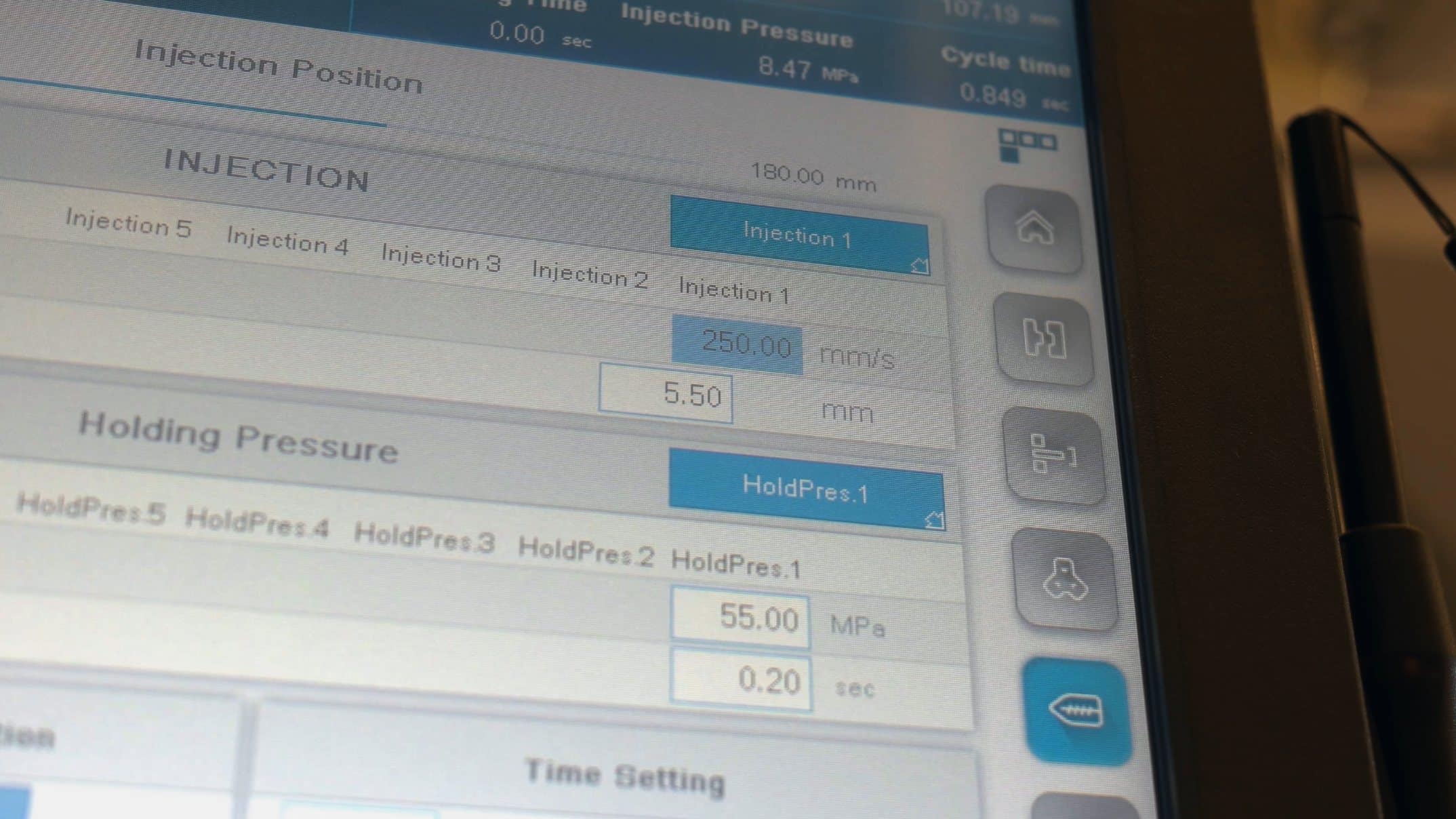

Think of us as an extension of your team. We guide you through every step of medical plastics manufacturing —from selecting the right biomedical polymers and molds to optimizing processes.

View Expert Consultation ServicesManufacturing

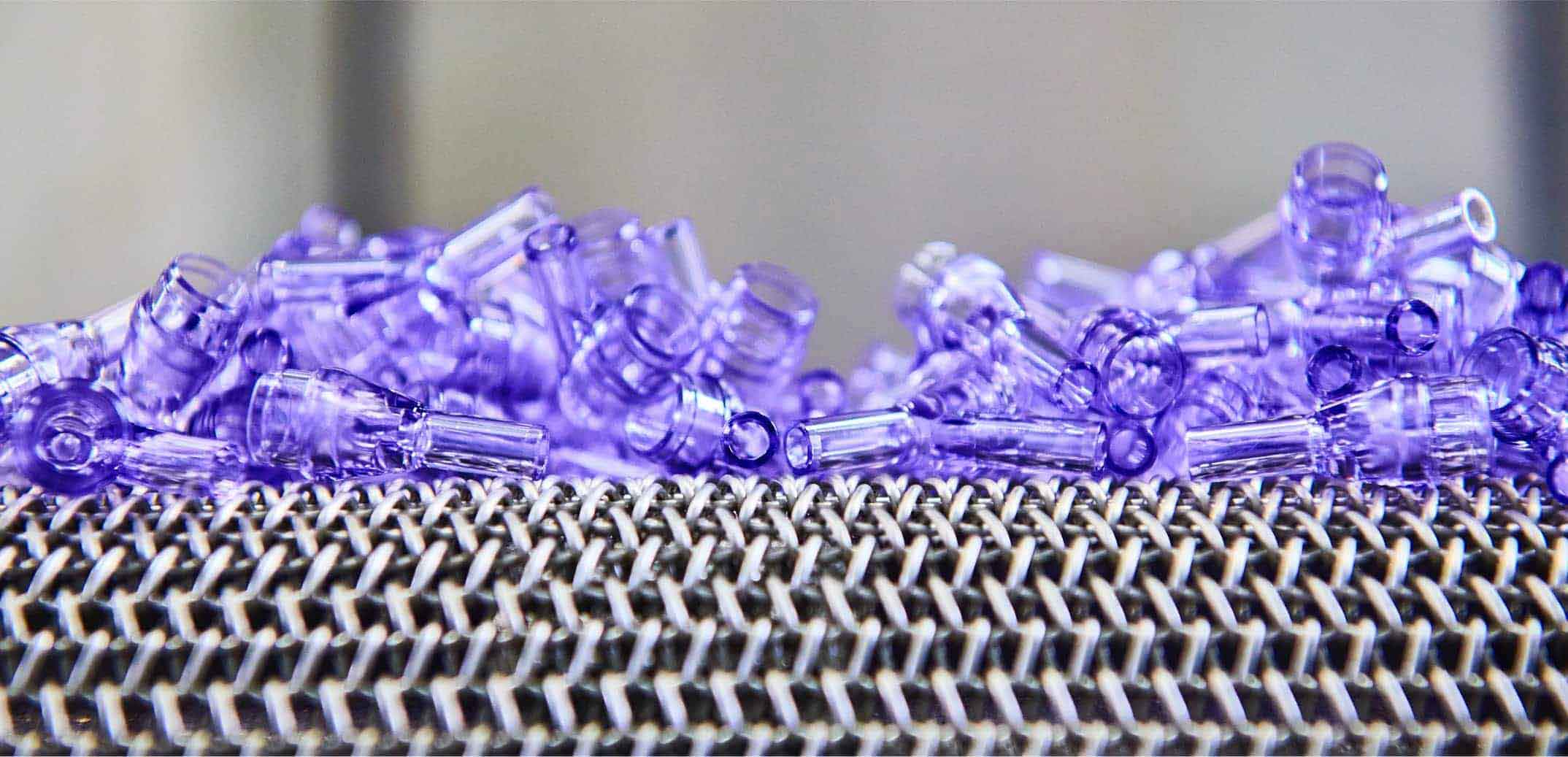

Precision, scalability, compliance—our medical plastics manufacturing delivers it all. With ISO 13485-certified medical plastic molding, we ensure consistent quality and long-term reliability.

View Manufacturing ServicesPackaging

The right packaging protects more than just your product—it protects your reputation. We provide cleanroom assembly, sterile packaging, and private-label solutions, ensuring product integrity.

View Packaging ServicesProcess Validation

From IQ, OQ, and PQ validation to full compliance support, we keep your medical plastic manufacturing process running smoothly and predictably. Because a true partner always has your back.

View Process Validation ServicesIVD Components and Devices

Precision matters, especially in diagnostics. We help you bring accurate, compliant IVD components to market with confidence through our transparent approach.

View IVD Components & Devices